🛠️Gelatin Equipment

Gelatin equipment refers to the machinery and systems used in the production of gelatin—a protein derived from collagen, typically sourced from animal bones, skin, or hides. The production of gelatin is a complex, multi-stage process, and specialized equipment is required at each stage to ensure efficiency, hygiene, and quality.

⚙️ We provide gelatin production and processing equipment

Raw Material Pre-treatment Equipment: (bones/skins Crusher), (Washer Machine), (Degreasing Machine).

Acid/Alkali Soaking Tanks: Used to soak raw materials in acid or alkali solutions to break down collagen and remove minerals (like calcium).

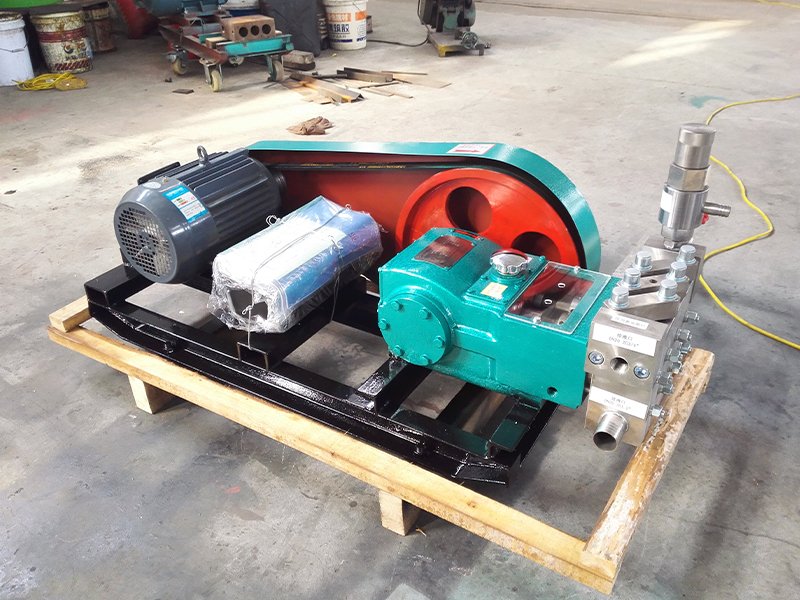

Extraction Equipment: Multi-stage extraction tanks: Sequential heating and water extraction to dissolve gelatin from pre-treated material.

Filtration & Purification Systems: Plate and frame filters, Centrifuges, Decanters, Removes solid residues and improves clarity.

Evaporation Equipment: Vacuum evaporators: Concentrate gelatin solution by removing excess water.

Sterilization Equipment: Typically uses UV or heat-based sterilization to eliminate bacteria and pathogens.

Drying Systems: Gelatin belt dryers and fluidized bed dryers, Converts concentrated liquid gelatin into sheets or granules.

Milling and Grinding Equipment: Turns dried gelatin into powder form for final packaging.

🌍 Applications of Gelatin

Food industry: Candies (gummies), marshmallows, dairy products, capsules.

Pharmaceutical: Capsule production, wound dressings.

Cosmetic: Facial masks, creams.

Industrial: Photography, matches, glue.